3 Major Signs Of Effective Corrosion Control In Clean Rooms

Published : 22 Jul 2022

Author Name : Athicka Thasni, Business Development Executive

Is it effective? This is a question that we ask ourselves after adopting corrosion management measures. Corrosion control units and corrosion monitoring units are designed to control equipment failures and reduce downtime. Whatever kind of corrosion monitoring unit we employ we must get data that proves the effectiveness of corrosion control from it. AQOZA offers corrosion control units that work on gas-phase filtration technology to maintain a corrosion-free environment. The real-time reading of temperature, relative humidity, and the concentration of PM 2.5 along with when the particle filter and media filter need to be replaced is displayed within the corrosion control unit offered by AQOZA.

But what are some practical signs that tell us effective corrosion management is underway? In this article, we will look at some of those signs

Signs of effective corrosion management

Reduction in Cost

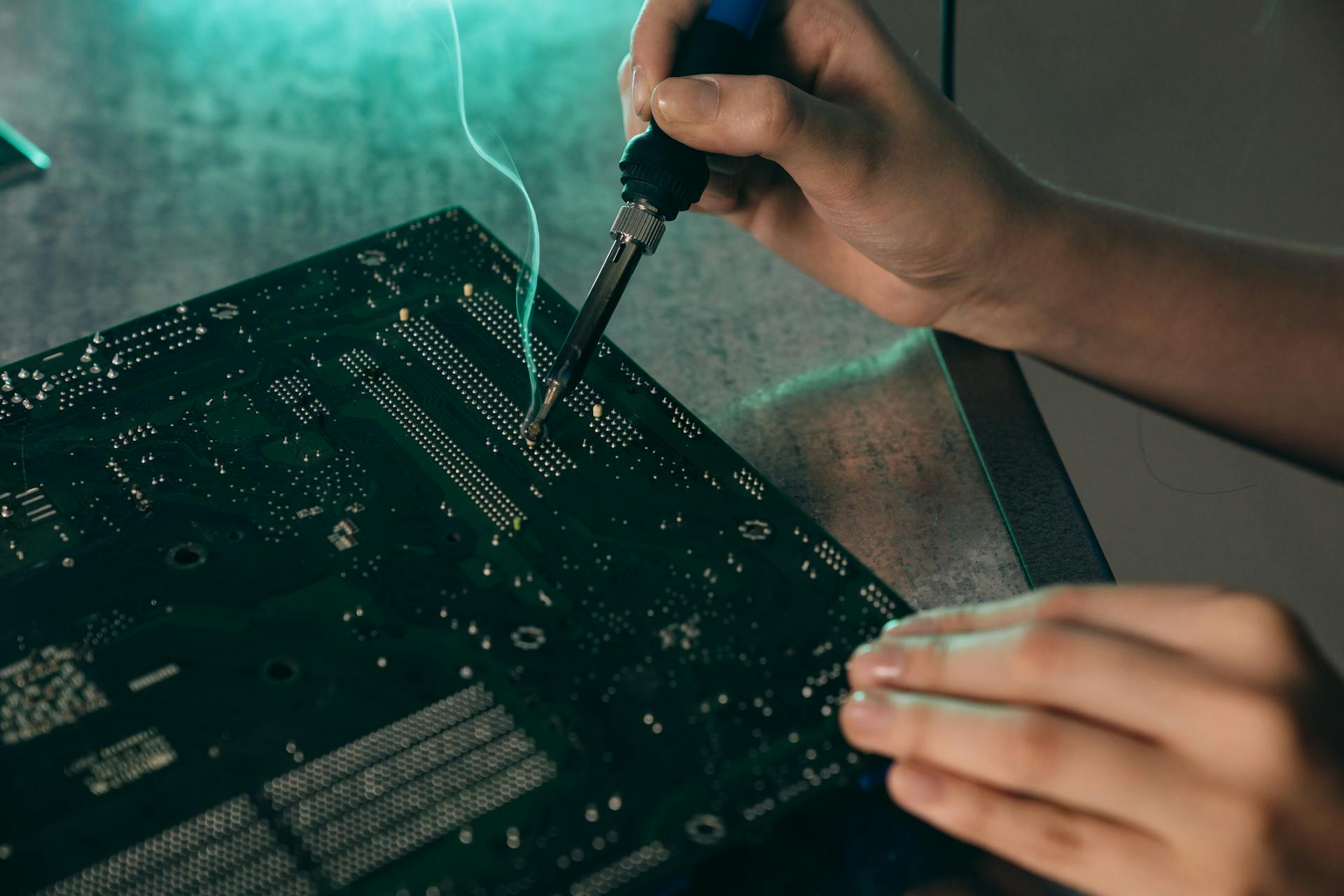

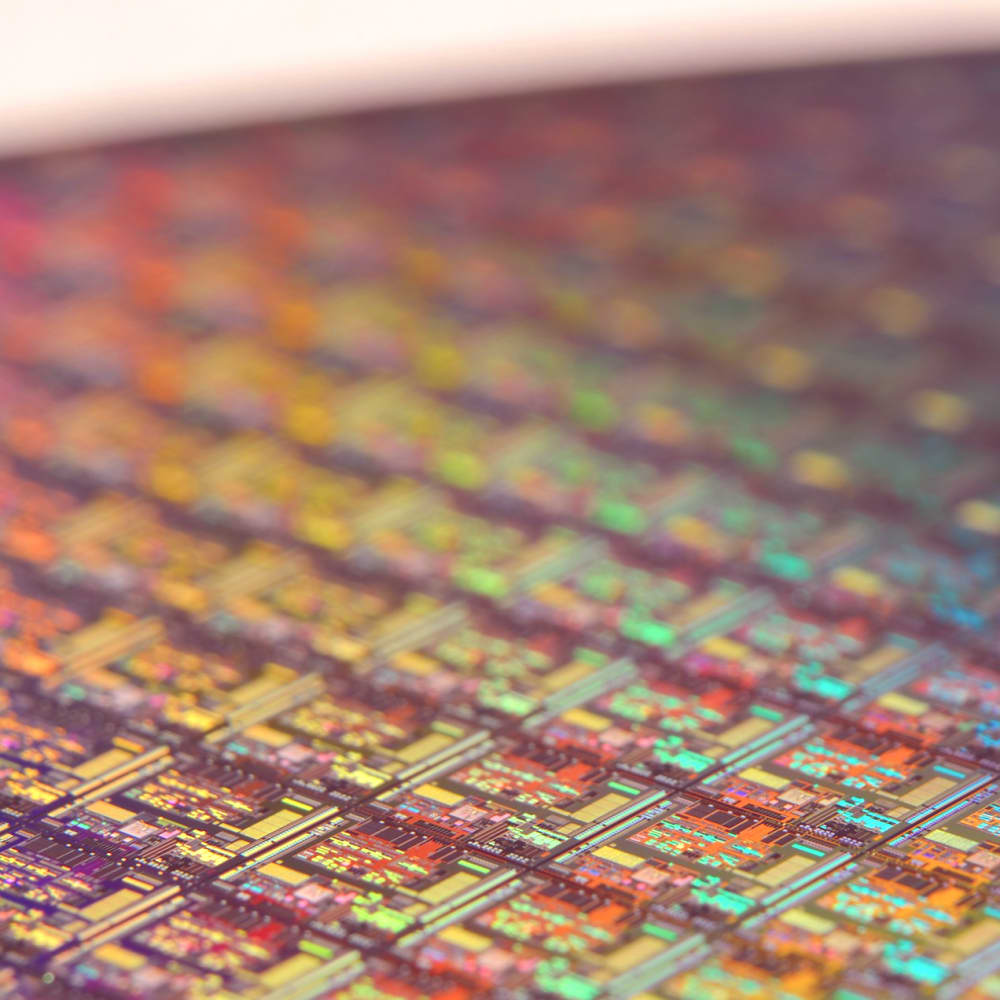

Electronic component failure can be associated with the concentration of airborne contaminants present in the environment. With proper corrosion management, the rate of failure of components decreases which further reduces the replacement costs. Since a major cost of running a facility is associated with maintenance, proper corrosion management systems help increase the longevity of electronics in control rooms, server rooms, or data centres thus decreasing the operational cost and increasing the revenue of the business.

Better efficiency

Efficiency increase can be associated with a proficient performance of the facility with proper corrosion control and monitoring techniques. Corrosion control prevents sudden and catastrophic failures of components which significantly reduces the downtime. Less downtime means more operational hours and less maintenance required.

The continuous corrosion monitoring employed helps in determining corrosion at an early stage and preventive measures can be carried out to resolve issues. All these add up to increase efficiency.

Increase in safety

With time every piece of equipment deteriorates and becomes susceptible to corrosion. Electronics are also not free from this natural phenomenon. When corroded, they can cause catastrophic failures by short circuits which is a challenge for both infrastructure and life. Fire suppression systems in data centres work by flooding the room with inert gas to kill oxygen levels. This method displaces oxygen and finally kills the fire. While suppression is a good technique used to protect equipment, it is not so good for human life. In a worst-case scenario, a technical person working in the room away from the point of fire will likely miss the indications if he is busy with his computer and using his headphones. Corrosion control and monitoring increase the safety of both the facility and human life.

We at AQOZA technologies are experts in corrosion monitoring and control. Being a specialist vendor in gas phase filtration and monitoring, AQOZA offers optimum performing corrosion control units and corrosion monitoring units to various industries. Get in touch with us to know more!!!