Why clean air is necessary for critical medical equipment to Survive?

Published : 21 Mar 2024

Author Name : Gifty Francis

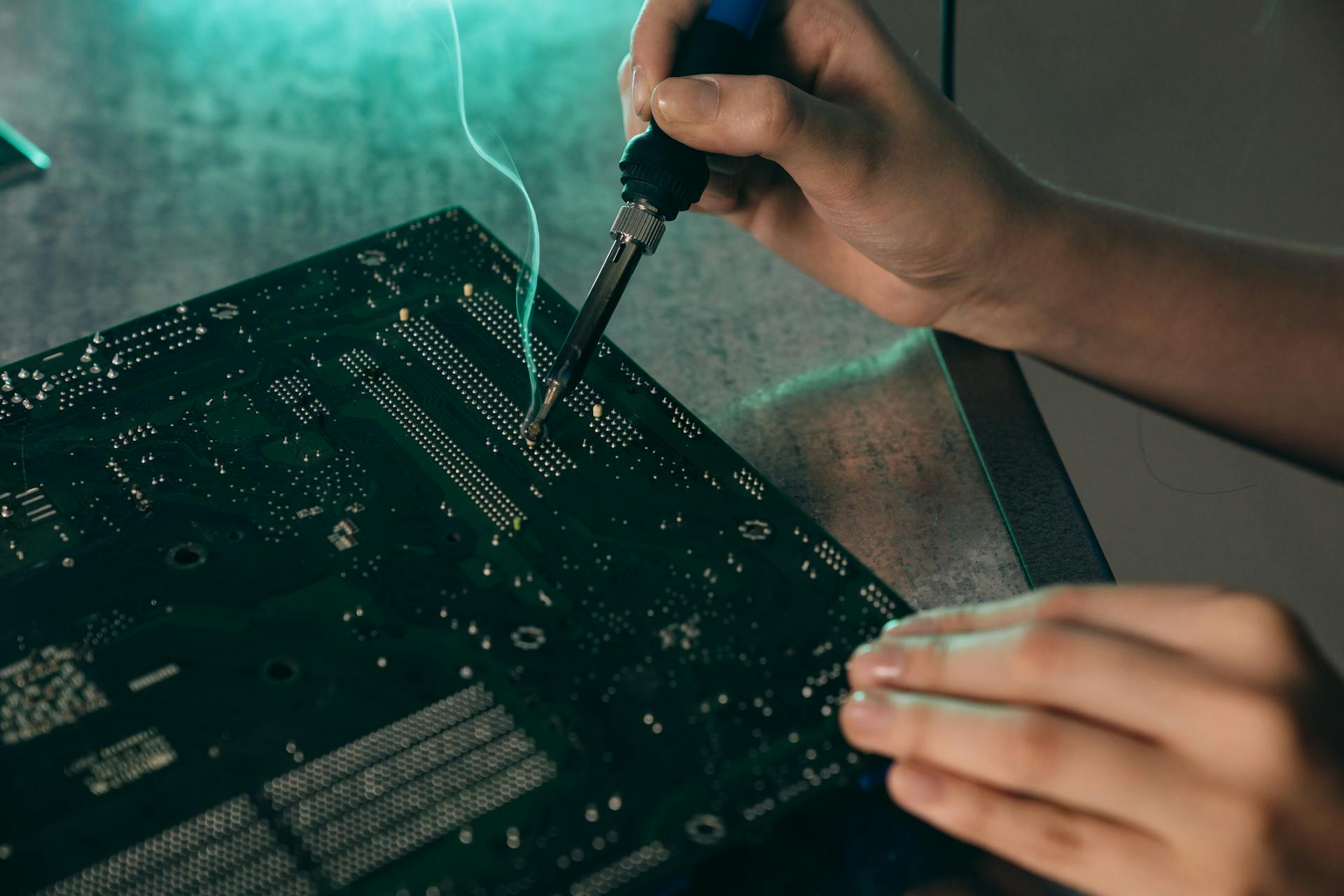

We know it’s crucial for human beings to have a clean environment for efficient breathing and to sustain a healthy life. Similarly, all electronic equipment needs a clean-air environment to function. For critical medical equipment, which serves as a lifeline in many scenarios, a requirement for an infiltration-free environment is crucial.

Impact of Unclean Air

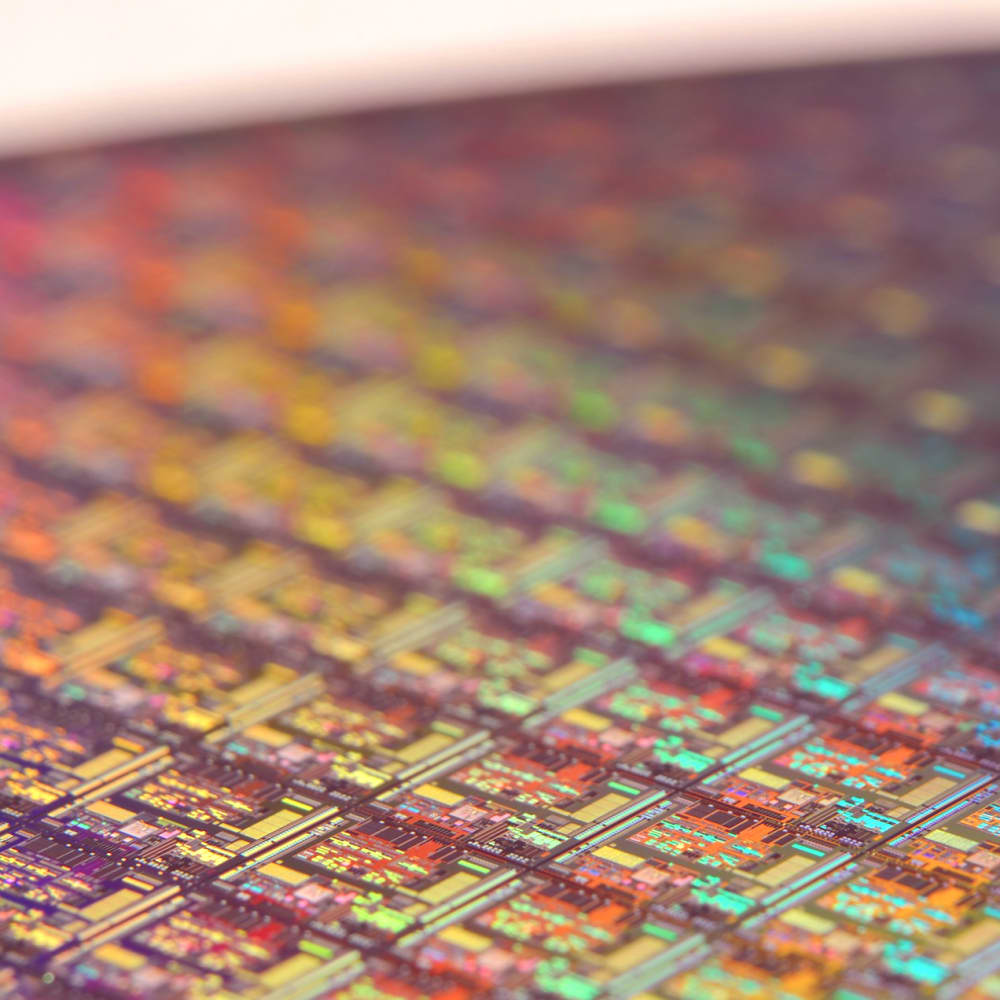

When the air is not clean, gaseous infiltrates can cause corrosion and failure in electronics, including medical equipment. As medical equipment becomes more sophisticated and complex, medical institutions and facilities must invest significantly in obtaining CT scanners, MRI machines, and X-ray machines. These machines require an apt environment to produce accurate results.

The rooms where critical medical equipment is functioning are vehemently called clean air rooms, but how clean they are is a matter of concern. Are the filters used in these rooms designed to fight gas phase molecules? If not, then you are in big trouble as the corrosion of equipment is caused by gaseous infiltrates and not particle infiltrates.

Atmospheric Factors Affecting Medical Equipment Life

- Gaseous Infiltrations: Indicative of pollution levels, gaseous infiltrations can significantly impact the performance and lifespan of medical equipment.

- Temperature Fluctuation: Temperature variations can result in condensation, which is detrimental to electronic components.

- Humidity Level: High humidity levels can lead to moisture accumulation, increasing the risk of corrosion and equipment failure.

Sources of Atmospheric Pollution

Sources of gas-phase atmospheric pollution in medical facilities can include open drains, sewage treatment plants, industrial emissions, and even cleaning agents used in clean air rooms. These pollutants, combined with temperature fluctuations and high humidity, can accelerate atmospheric corrosion.

ASHRAE Recommendations

To maintain optimal performance and longevity of medical equipment, ASHRAE recommends maintaining a temperature between 18-27 degrees Celsius and a relative humidity between 40% to 60%.

Vulnerable Areas Requiring Clean Air

In medical institutions, several areas house critical equipment that require clean air to prevent corrosion and ensure optimal functioning:

- PET, CT Scan Rooms

- MRI Rooms

- Ultrasound Rooms

- Operation Theatres

- Radiology Rooms

- Mammography Rooms

- Angiography Equipment

- NICUs, ICUs etc.

These areas are crucial for patient diagnosis and treatment with highly sophisticated equipment making it imperative to maintain a corrosion-free environment.

Achieving a Corrosion-Free Environment

Gas phase filtration solutions that remove gaseous infiltrates which cause damage to electronics are the most effective solutions to this problem. The corrosion control units work on this principle and ensure an infiltration-free atmosphere for the equipment giving more meaning to the name - Clean Air Rooms. They are designed based on the ANSI / ANSI 71.04 -2013 standards.

Corrosion Monitoring units can both actively and passively tell you about the corrosion severity level of the clean rooms, you may use this information to employ a corrosion control unit, if required, or check the efficiency of its working.

Contact us to learn more about achieving a corrosion-free environment for critical medical equipment.