Gaseous Corrosion – Reason for Electronics Failure

Published : 11 May 2022

Author Name : Gifty Francis

All electronics, primarily the Printed circuit boards are very susceptible to corrosion under certain conditions. The main reason for this is that the materials selected for the manufacturing of electronics are not inherently corrosion-resistant, or even treated to high degrees of resistance. The electronic equipment fails if the working environment is severe. Replacement of failed electronics is accompanied by an increase in downtime and the risk of health hazards.

How does electronic failure due to corrosion occur?

In this article, we will see the major reasons for electronics failure due to corrosion. There are a few major reasons for that.

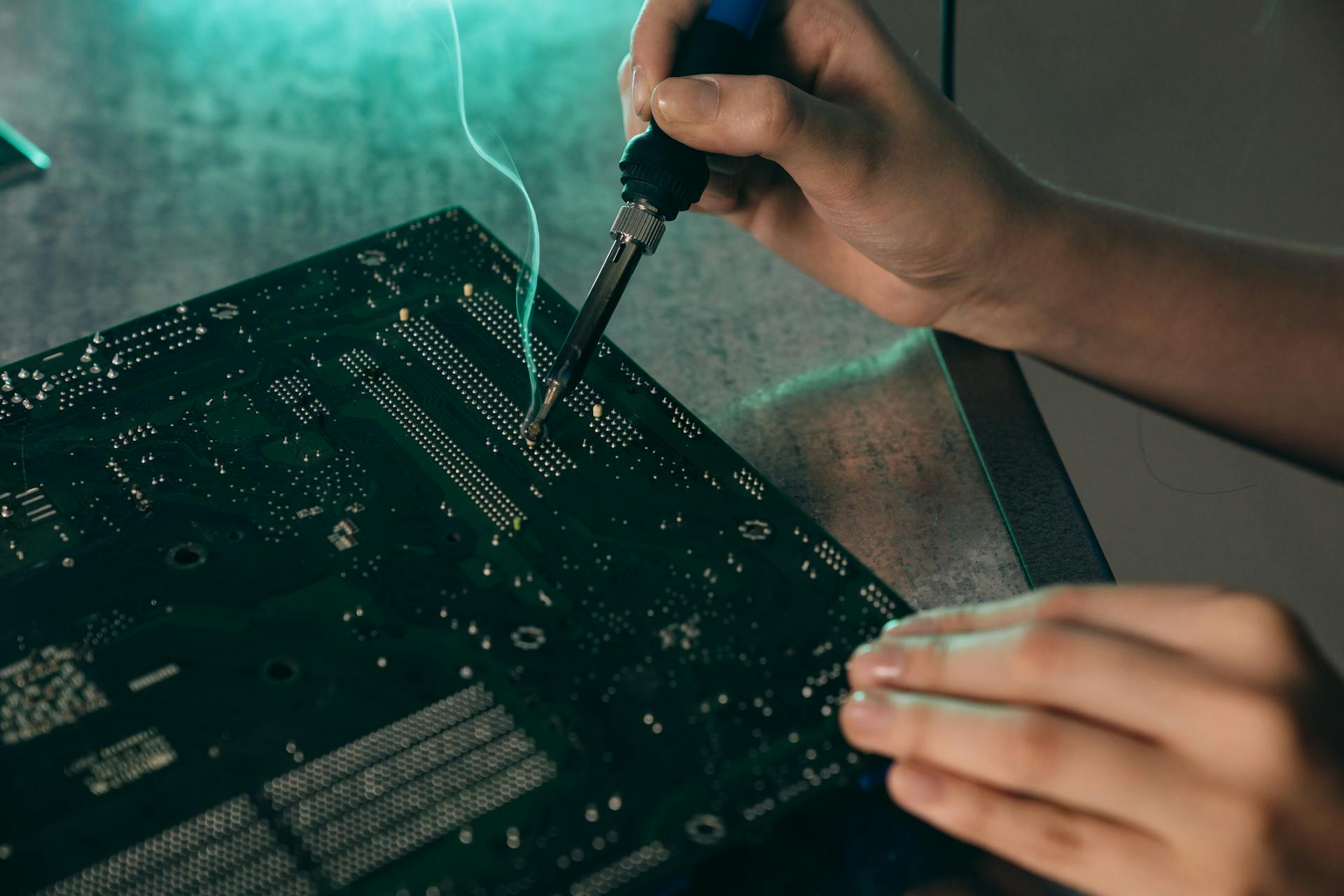

Corrosion due to the manufacturing process

Components like tactile switches are mounted on a PCB by hand soldering technique due to the presence of copper in PCB laminations. Copper has a very high heat capacity and as a result, heat is generated during the automated soldering process which results in weaker solder joints. Hand soldering is performed by using a non-clean flux which is believed to leave minimum residue, but in reality, it leaves large residues and the level mostly depends on the technical skills of the person performing the soldering operations. The degradation of flux residue happens at 250o-350o C but in the case of hand soldering regions near the solder will experience much lesser temperature leaving a huge amount of unreacted flux on the boards.

This flux residue inside can act as a di-electrical barrier and can cause the equipment to fail at a very early age. The silver and tin used in the electronics are getting corroded easily because of the flux present, as these accelerate the corrosion and this results in a short circuit failure of electronics.

Corrosion due to harmful work environment.

The exposure of electronics to an environment where humidity, temperature, and atmospheric pollutants are not controlled can result in corrosion. The atmospheric pollutants mentioned are H2S, NOx, SOx, and chlorides. Among these pollutants, H2S and SO2 act as the main source if humidity levels are high. The rate of corrosion also depends on the industry and its location. The electronics used in the rubber manufacturing Industry or paper mills can cause failures due to corrosion in just a few weeks.

Silver-plated copper lead frames can get corroded easily by the aforementioned gases if any Sewage treatment plant, heavy traffic, or open drains are located near it. The concentration of these gases can be as low but still cause significant corrosion. The lead-free regulations for electronic equipment have increased the sensitivity to corrosion and failures.

The entrapment of corrosion-causing gases in a severe working environment requires specialist help. Being a specialist vendor in gas phase filtration and monitoring AQOZA offers optimum performing corrosion control units to various industries. Get in touch with us to know more!!!