Protecting Petrochemical Facilities from Corrosive Gases

Published : 03 Sep 2024

Author Name : Gifty Francis

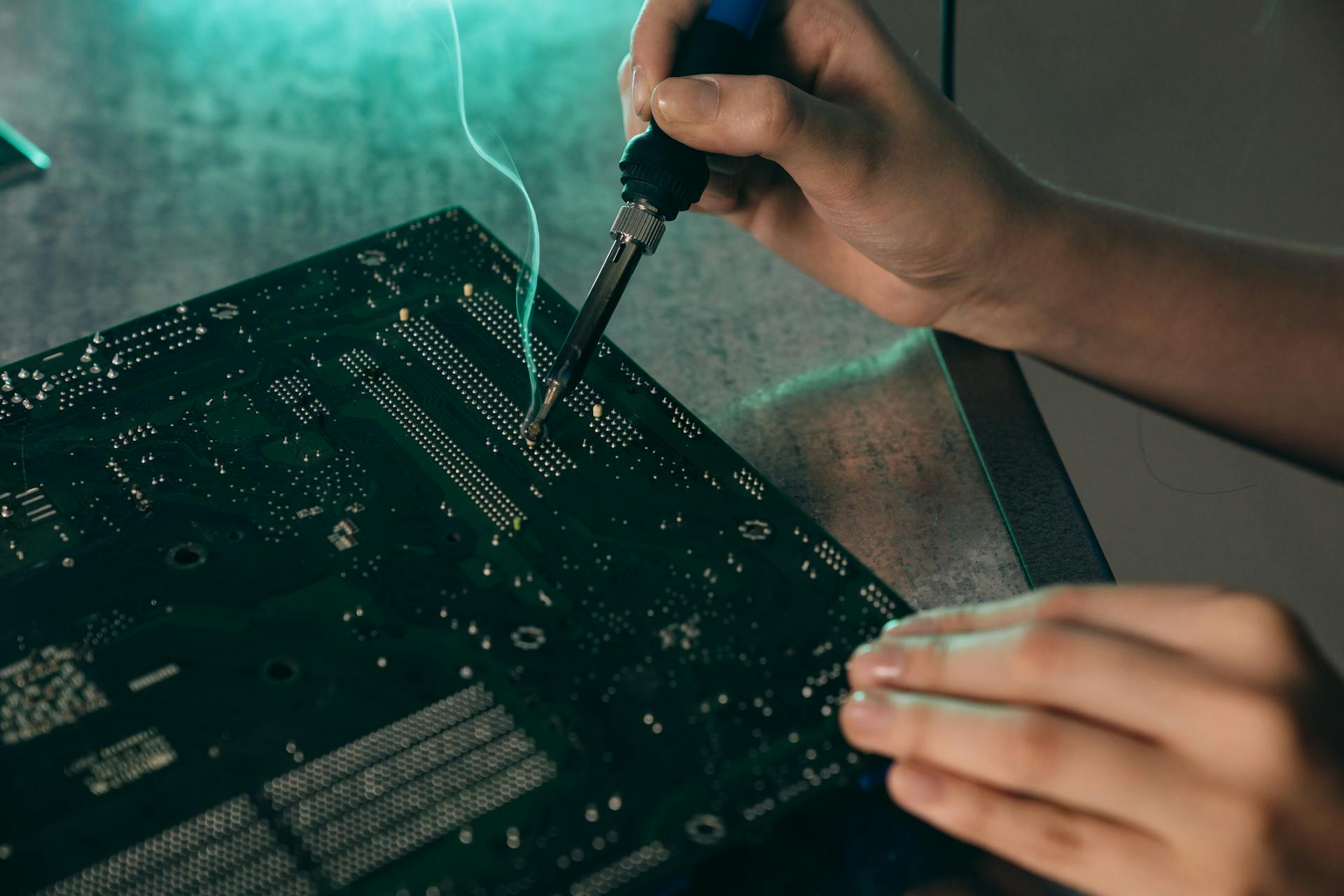

The Role of Electronics in Petrochemical Facilities:

Electronics are the backbone of modern petrochemical facilities, ensuring smooth operations, safety, and efficiency. They control various processes, monitor conditions, and provide critical data. From managing machinery to ensuring safety protocols, electronics play a vital role in keeping the facility running effectively.

Why Prevention is Crucial

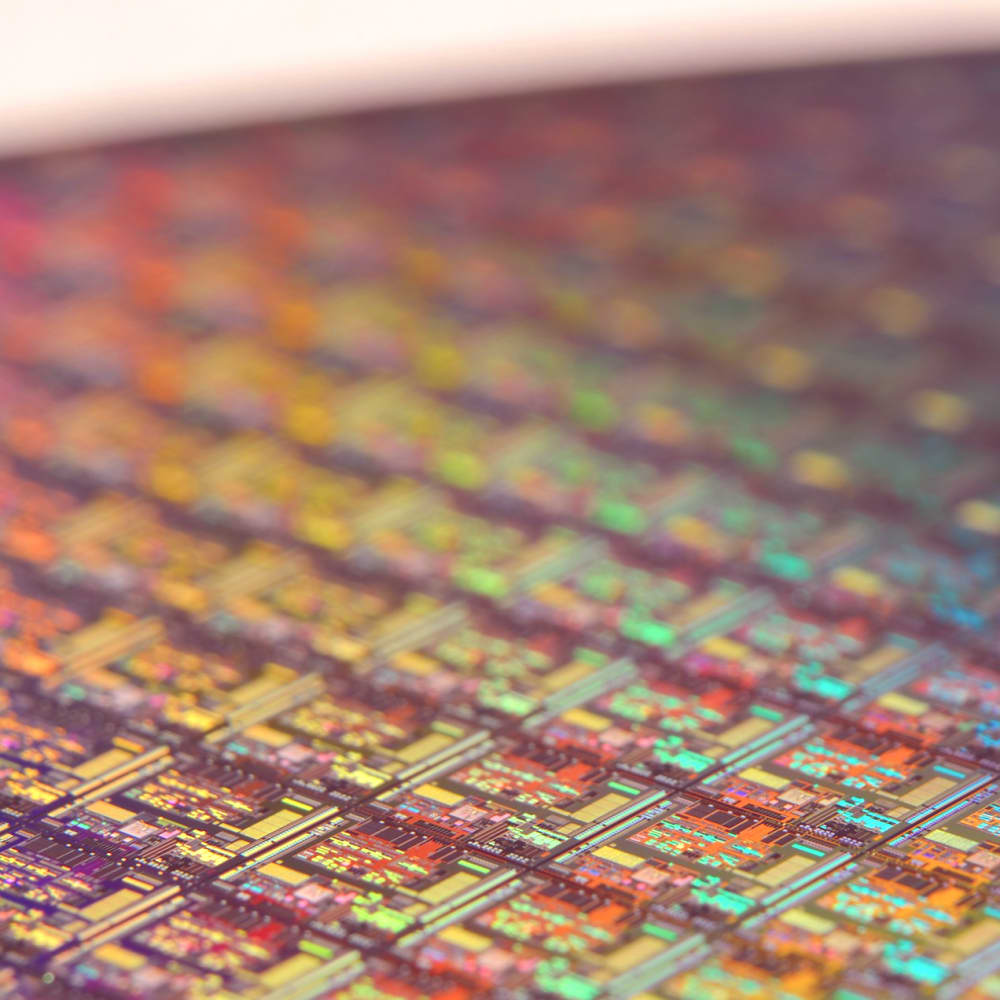

Corrosive gasses, such as hydrogen sulfide and sulfur dioxide, can severely damage equipment, leading to costly repairs and dangerous situations. Prevention is crucial to maintaining the integrity of the facility. By addressing potential corrosion issues, facilities can avoid premature and other failure of critical electronics which leads to the unexpected down times. It also helps in extending the life span of equipment, and always ensure a safe working environment for humans and equipment.

Benefits of Corrosion Control

Implementing corrosion control measures offers numerous benefits:

- Enhanced Safety: Preventing corrosion helps maintain the structural integrity of equipment, reducing the risk of leaks, spills, and accidents.

- Cost Savings: Regular maintenance and corrosion prevention reduce the need for expensive repairs and replacements. It also helps to prevent downtime.

- Operational Efficiency: Well-maintained equipment operates more efficiently, leading to smoother operations and less downtime.

- Longer Equipment Life: Corrosion control extends the life span of equipment, ensuring it remains functional and reliable for longer periods.

- Maintains Manufacturer Warranty: Corrosion control maintains a healthier environment for your electronics and helps in maintaining the warranty conditions as demanded by the manufacturer.

Gas Phase Filtration: An Effective Solution

Gas phase filtration is a powerful tool in the fight against corrosive gasses and odors. This technology uses specialized filters to remove harmful gasses and contaminants from the air. Here’s how it helps:

- Odour Control: Gas phase filters capture and neutralize odorous compounds, significantly improving air quality and creating a more pleasant working environment.

- Protection Against Corrosive Gases: These filters are designed to remove corrosive gasses before they can reach sensitive equipment, thus preventing corrosion and extending the life of electronics and machinery.

- Increased Safety and Reliability: By keeping corrosive gasses at bay, gas phase filtration enhances the overall safety and reliability of petrochemical facilities.

Effective Corrosion Control Measures

Effective corrosion control involves a combination of preventative and monitoring strategies to ensure the long-term integrity of equipment and facilities. Two key aspects are real-time corrosion monitoring and proactive corrosion control:

Real-Time Corrosion Monitoring: Utilizing advanced sensors and monitoring systems, real-time corrosion monitoring provides continuous data on atmospheric corrosion. This technology allows for the early detection of corrosion, enabling timely interventions before significant damage occurs. By tracking corrosion rates and identifying problem areas, facilities can implement targeted maintenance and repairs, thereby reducing downtime and extending equipment life.

Corrosion Control: In addition to monitoring, implementing corrosion control measures will filter the gases from both within the facility and from external sources that could corrode critical electronics. This not only provides a safer environment but also enhances control over the entire facility's processes.

By integrating real-time corrosion monitoring with control strategies, petrochemical facilities can significantly enhance their ability to manage and mitigate the effects of corrosive gases. This comprehensive approach not only protects critical equipment but also ensures the safety, reliability, and longevity of operations.

Have more questions or queries, Feel free to contact the experts.